Join the collective

Change the world

Join the revolution using AI to change the world

My 1st gen slow autonomous bot. Only one processor has to stop and look. The 5- processor fast bot is shown below.

I have applied advanced AI modelling to hot rod engines. See below for more information.

Ultimately, we must apply much more AI to medical research. A lot has been done but until cancer is “conquered” we are sacrificing our families and fellow human beings.

We are drowning in data and starved for knowledge! Data mining, data analytics, data harvesting, AI and Machine learning are very easy to do very poorly! Our goal has to be to do it better and help set realistic expectations. Unrealistic expectations is our biggest challenge to advancing AI and causes most of the disappointments.

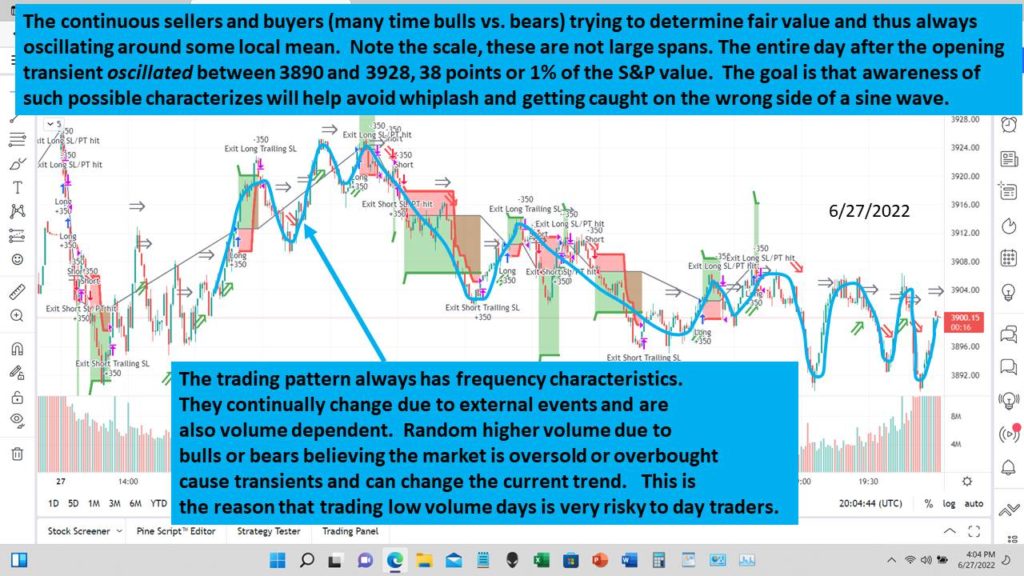

An interesting AI application that everyone tries and wants. Here are some basic thoughts that many overlook.

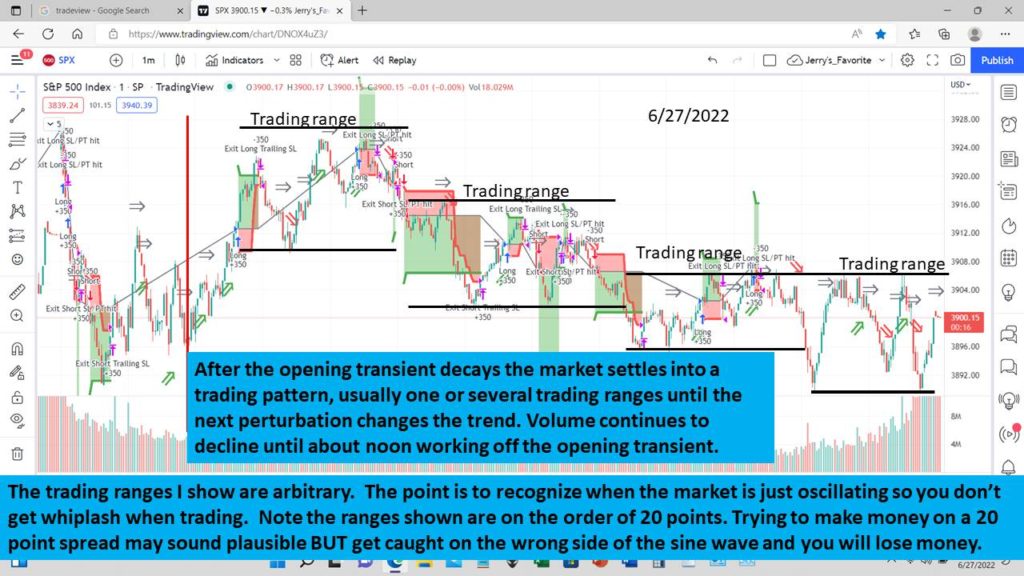

Many try using AI to predict the stock market. Some of the biggest investing firms hire numerous Applied Mathematicians and Physicists. Short term trends are “very” easy to predict if you see the real time stock’s order flow, the potential orders with their offered buy and sell prices, and the buy/sell spreads. The big firms have this information available, and computers can trade the trend in real time with high probability, greater than 50%, of success.

To have a successful algorithm to trade stocks without the above information and without a computer timing the trades autonomously a successful algorithm, in my opinion, needs access to and ability to interpret news feed, for political and economic information, a preprogramed algorithm to recognize, interpret and judge sentiment changes and probable market reaction and commodity price inputs, futures inputs, short selling and option inputs and foreign market and currency inputs.

I worked in high technology for many years before retiring. I did a lot of classified work and some unclassified work and hold two patents. While working for large corporations any side interest in technology that I delved into that was not part of my corporate assignments I considered and published as hobbies so there was no conflict of interest or concern of intellectual property ownership. Since retired I have started my own company and I am building on the technologies that were previously used in my hobbies and described below

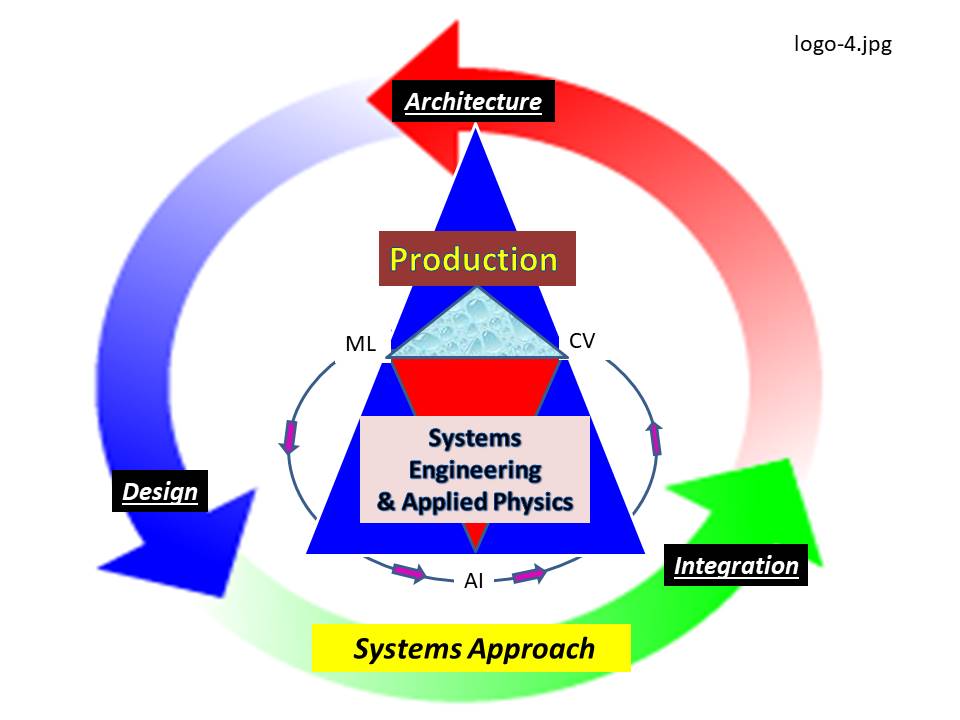

My LLC logo that represents my philosophy and systems approach to all my projects. Don't worry this web site is not a sales pitch.

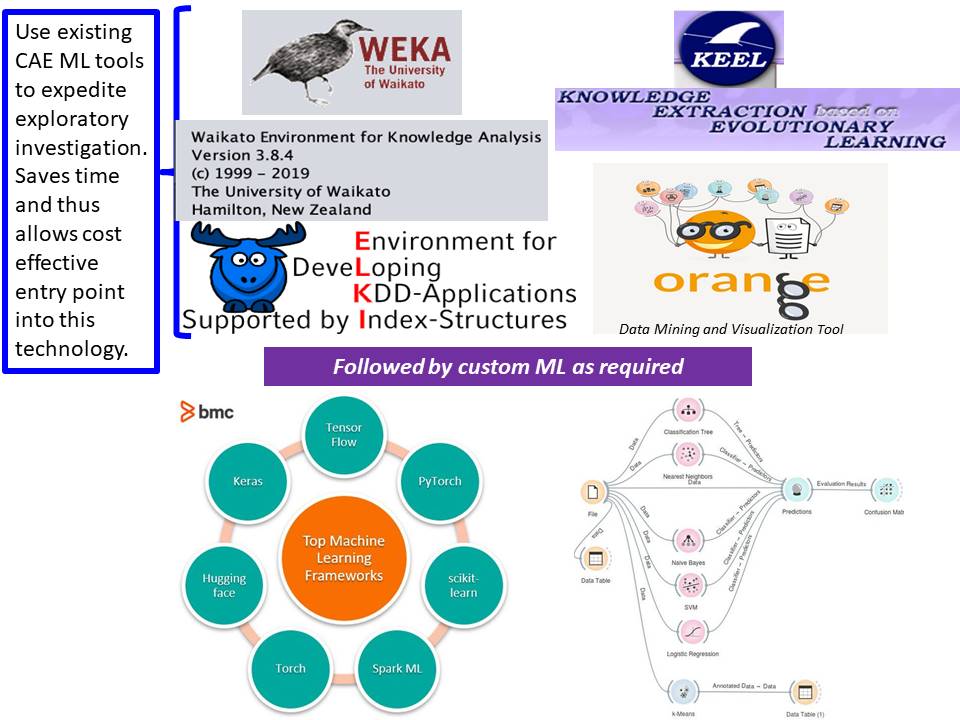

Tools I use for all my projects, either hobby projects or professional projects.

Videos of some of my AI projects

Before I retired, I published the technology that I implemented into my hobbies that were not related to my work on YouTube and Instagram. Since I was still working for a high technology company, I kept the descriptions very brief. Here I am expanding the descriptions and giving insight into some of the possible applications. I hope the systems level approach and the building block approach is apparent.

One of my goals was to understand the technical difficulty of building these types of CV and AI applications. The scary part of this modern world is that I did these projects in days by piecing together code on the internet and adding minor amounts of "glue" code to enable the drone and the bot to act as a system. It was also very easy to analyze the complexity of hot rod engines using AI tools and techniques widely available on the internet as shown below. Think what governments with large numbers of engineers can do AND also ask why we have not conquered cancer.

Development of tracking algorithm using my fast autonomous bot as a target. This algorithm does not use target identification. Its use is intended to allow fast tracking after the target is identified and the drone transitions from search and target identification to track. It uses CV2 template matching algorithm combined with a CV2 salient motion tracking algorithm.

This video shows my Tello drone flying, It shows detection and successfully closing its tracking loops on my stationary “fast bot”. Images of the fast bot were used to train a custom yolo detection algorithm to identify my fast bot as a unique and custom object. The upper left video is a recording of the drone in flight and video from the drone showing detection on the computer monitor included inside this video. A blue hand drawn circle shows the location of the drone since the drone is small in the video. A red line was inserted into several frames to draw attention to the detections shown in the lower left screen, the drone’s video, and on the monitor in the upper left frame. The lower right screen shows the response of the tracking loop. Since lock is lost frequently it is planned that once the target is detected and identified that I switch to the object tracking shown in the video above.

This video used the Tello drone camera as the video source. As can be seen yolo did not identify my bot as the Fast Bot so my next step was to train yolo with specific weights to detect my fast bot. Note the speed of the detections in this video. This was drone video transmitted to a notebook computer in real time. Just think what foreign governments can do. You probably have seen video where China recognizes and tracks everyone from cameras on their public streets.

This video shows a Tello drone that is programmed with a face search routine, then face detection, then detect and track the target, a specific face, mine. It says “look, look, look” when searching, Arduino Talkie library did not include search. It says “look for next target, look for next target” if it detects a face other than mine. It say “target, target, target; target, target, target” if it sees me and then the drone tracks me. The left screen on the video monitor in the video is a search screen and updates always. The right screen on the video monitor in the video first appears when it recognizes me, the target, and updates when it is tracking me the target. It freezes if it is not tracking me. I did this in several days putting together pieces and parts of code from the internet. Just think what is done by foreign governments. There is commentary so turn on the audio if you want to hear the action.

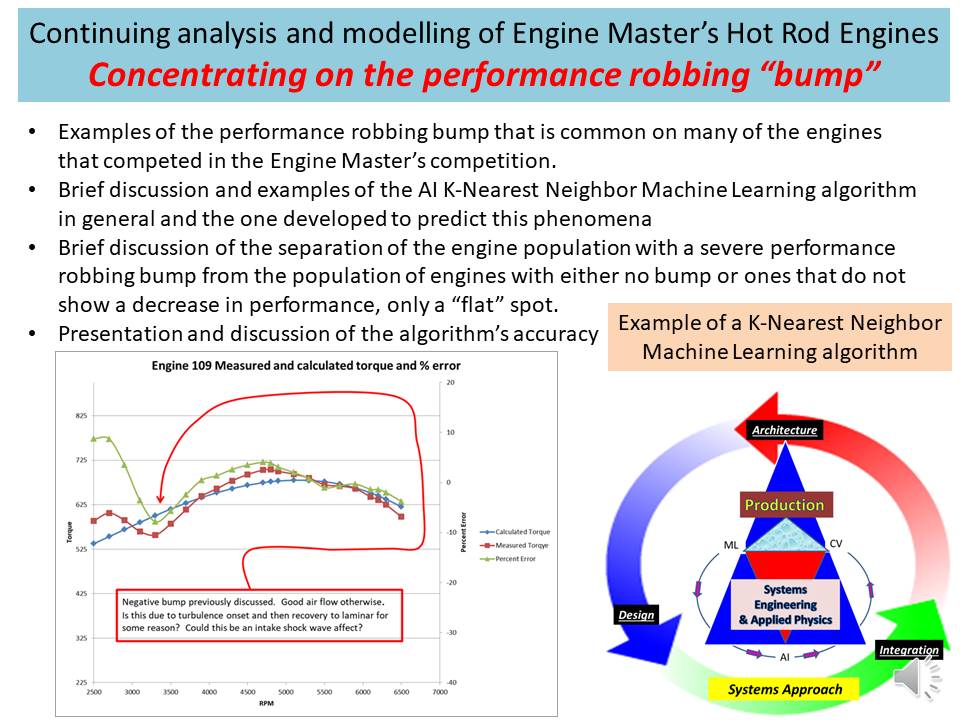

Artificial Intelligence and Machine Learning applied to a real-world design challenge: Analyze and derive AI/ML based Hot-Rod Engine Dyno Simulators

If you are going to rebuild an engine and you want to push the performance you will want the best you can get for your money. Many turn to the widely available software dyno simulation programs on the internet. However, they usually require that you choose multiple components from pull down menus that are limited and may not include your intended parts. You have no idea how the parts interplay and thus no idea of the predicted results if you build with different parts. Even if you build the exact engine with the allowed choices I have not found any documentation of the accuracy you can expect except for some comparisons to only one or two engines.

My goal is to give you a second simulator that only requires basic engine design parameters as input and the data base of the 186 engines that were used to derive it. The engines were part of the Engine Master’s competition. These are the best hot rod engine builders in the world and sell their engines for very high dollars. The database will allow you to find an engine that is similar to your planned build and give the dyno test results from the competition. I will show you data that indicates this simulator is 80% accurate for predicting average and maximum horsepower and torque and the associated RPMs for over 90% of the test cases.

Your reaction may be that 80% isn’t good enough, 20% error is too much? How accurate are the commercially available software dyno simulators? Additionally, when you have to substitute parts in the build that are not included in the simulation how sensitive is the simulation’s accuracy to the changes? The costs of the widely distributed simulators start at $60 dollars and go up substantially.

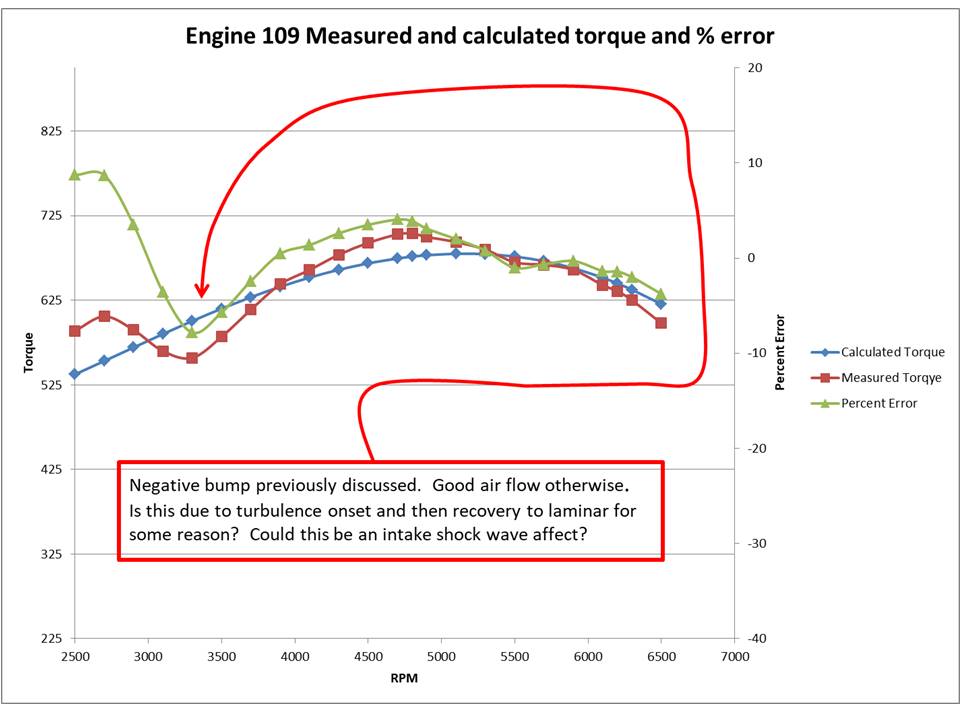

Additionally, I have created a simulator that predicts the entire torque curve per RPM and an additional simulator that predicts the probability that a power robbing phenomena will exist in your design. This power robbing phenomena is widely prevalent in many of these engines. This simulator will allow design changes to be made and determine if the probability of occurrence is reduced. These used very sophistic modeling techniques and I am selling them for a very modest $10 each. The link to my Github where the engine database and free simulator resides is shown in the video below and on my YouTube site and is repeated here for convenience:

jerryjavelin (github.com)

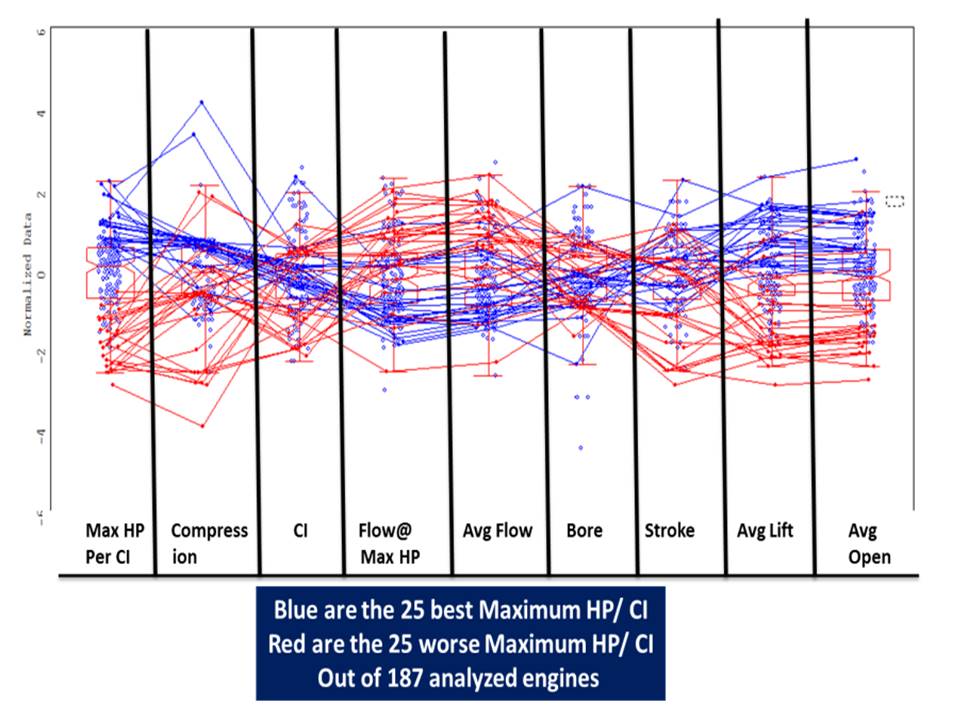

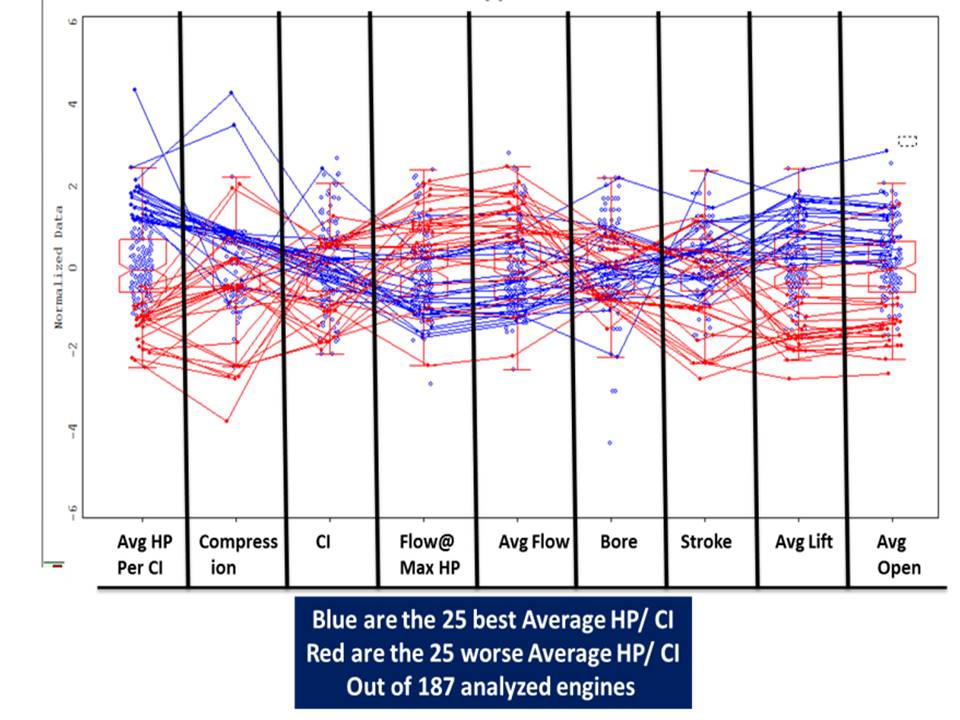

Only basic engine design parameters are required for all my simulators: compression, cubic inch displacement, bore, stroke, intake valve maximum lift and camshaft intake valve duration. All other parameters that are required are calculated from these. The charts below show that these determine 80% of an engine’s performance. These charts show that these parameters yield separation between the best and worst of the 186 engines. These engines were built by separate contestants all incorporating their own special parts and machining tricks.

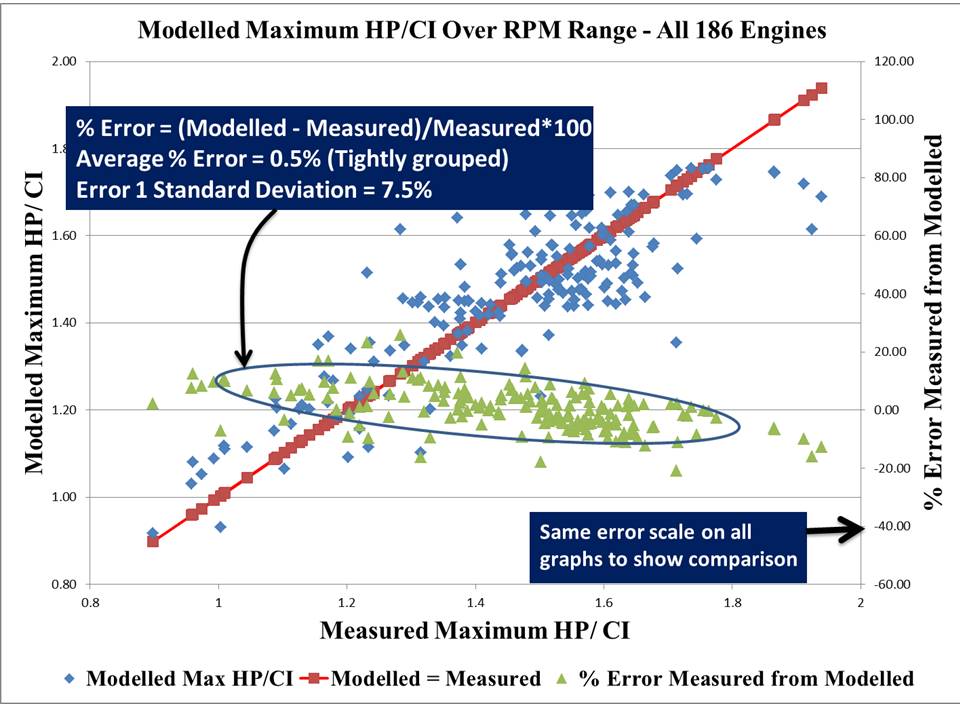

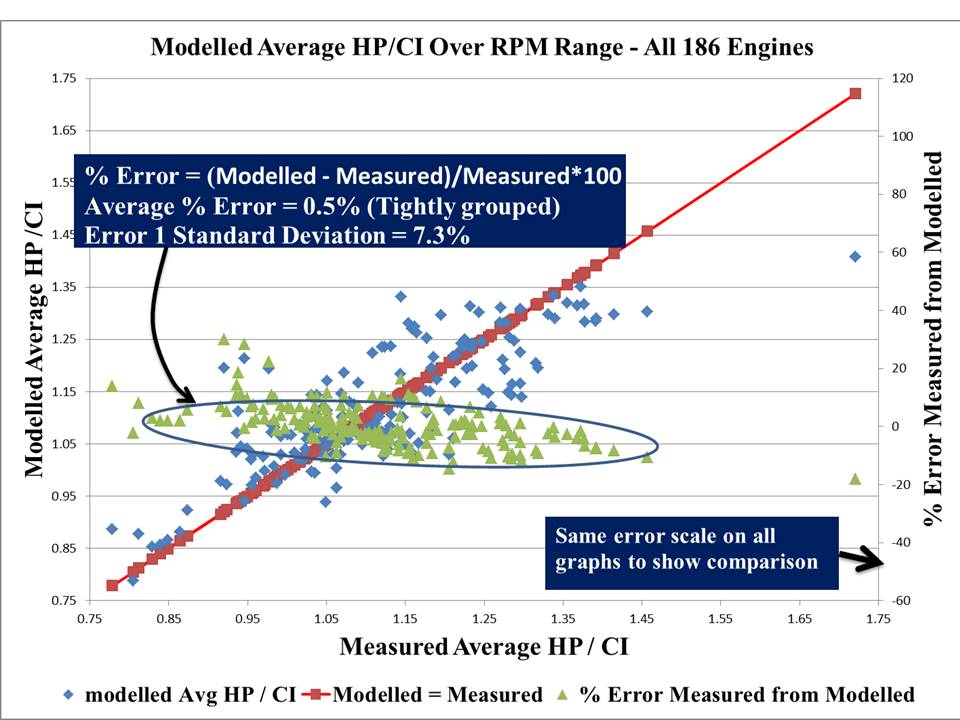

These charts show the dyno measured average horsepower per cubic inch and maximum horsepower per cubic inch, the calculated values and the errors for each of the 186 engines. For each of the engines the blue dot is located at the measured value on the horizontal x axis and the calculated value on the left-hand vertical y axis. If the measured and calculated values are the same there would be zero error and the blue dots representing the engine would lie on the red line. The green dot errors are read on the right-hand vertical y axis. There is a green dot that is associated with each blue dot.

Thus, the input engine population was based on a wide variety of parts and built by individuals that are experts using their own individual techniques. This wide variation allows the model to be very tolerant of design and build variation and still achieve decent accuracy. These graphs represent 8-dimensional space that show the input engine parameters as independent variables that cause separation in the dependent variable, the maximum and average horsepower per cubic inch. Looking for separation is one of the first steps. If there is no separation, then a model cannot be created from these variables that will predict good vs. bad performance

The blue text boxes show the average error and the standard deviation of the error for the 186 engines. If you never saw a demonstration of how averages can be misleading here is a perfect example. The good news is that three time the standard deviation will encompass 99.7% of the engines and that error is between approximately +/- 22.5%. Looking at the charts I believe you would agree that 90% of the green dots lie within +/- 20% on the right-hand vertical error axis.

This video is the introduction to my V8 hot rod engine simulator that predicts average torque, average horsepower, maximum torque and maximum HP and the associate RPM. Its input is simple engine parameters; cubic inches, intake cam duration, maximum intake valve lift, bore, stroke and compression. It describes the simulator, how it was derived and the location of the free engine simulator and the database of 186 engines from the Engines Master Challenge contests. These engines were used to derive the simulator and are on my GitHub. My GitHub link repository is shown on my YouTube page and shown below. It shows that with only these simple engine characteristic inputs it can achieve very good predictions, shows the accuracy and thus proves that the largest percentage of an engine’s performance is ONLY based on these parameters. I found it very interesting work and suggest you watch all the videos on this subject on my youtube channel. There is commentary so turn on the audio if you want to hear the explanations.

Before I finish my hot rod engine analysis that some may find boring even though it is intended as a demonstration of AI applications, I decided to show a preview of some other applications and techniques I am investigating.

Julia fractal set used as seed for AI generated art video. I’m experimenting with different disciplines that are then linked to or incorporated into AI. There are many applications of AI and computer vision (CV) linked to medical research and diagnostics. As a parallel application I want to explore the use of AI generated images and adversarial neural networks in medical research.

Another experiment with AI generated art video. This used a nebula picture as the seed. The difference from the fractal-based seed video is striking. The use of this technique as an input to adversarial neural networks with medical images as seeds will defiantly require an understanding of the algorithm behind the image and video generation.

Let’s finish the Hot-Rod engines analysis using AI and ML. Hotrodders may enjoy these videos, but the real purpose is to show how AI and ML can be applied to a very wide variety of complex real world challenges.

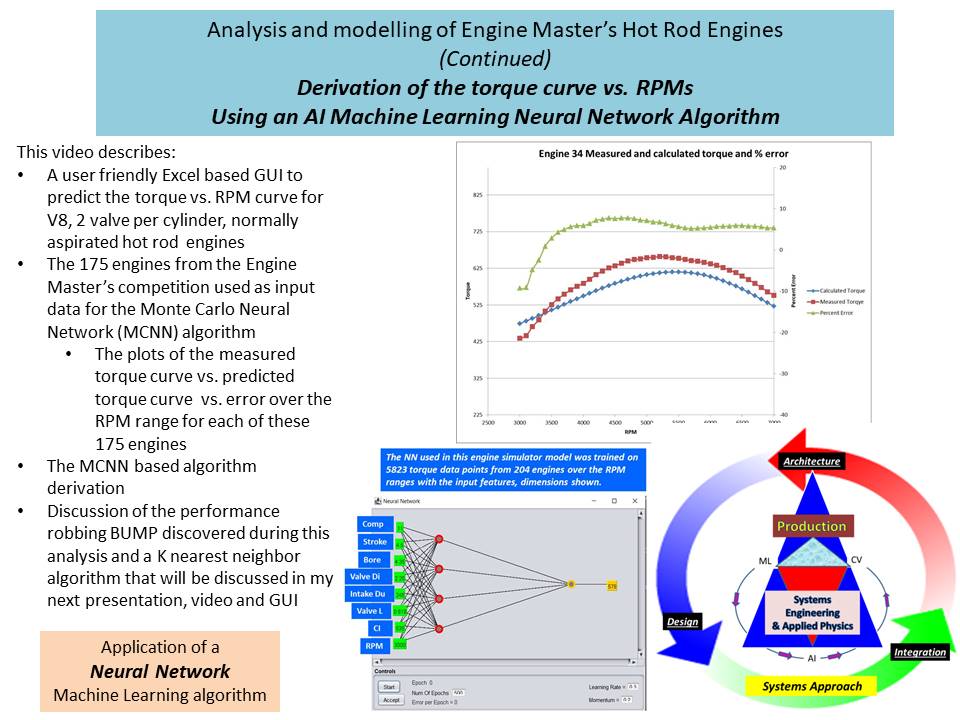

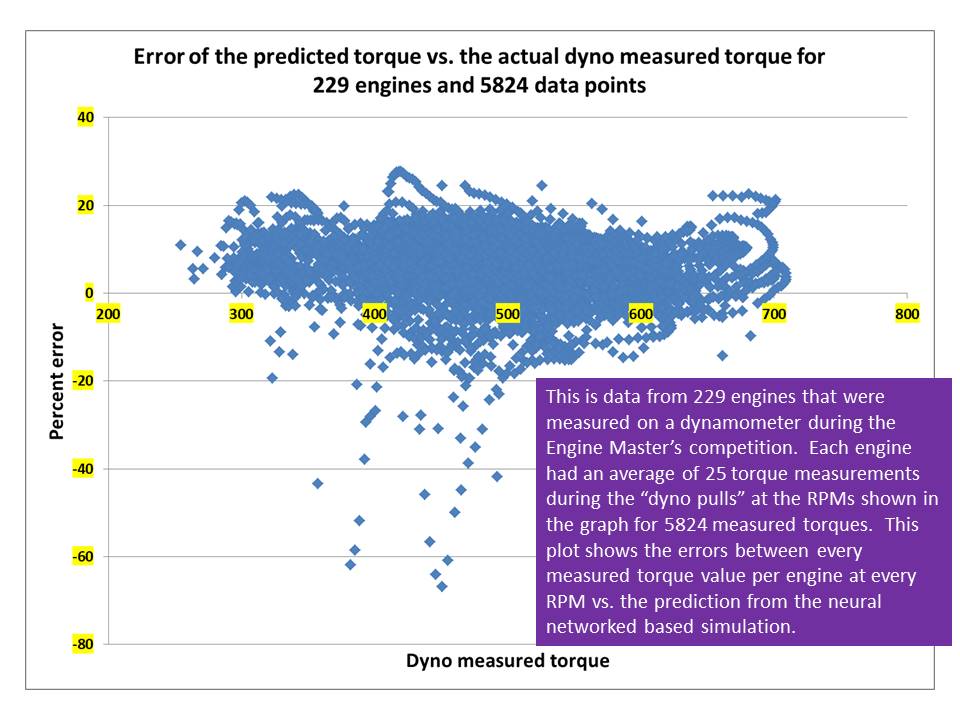

The next task will be to create a user friendly Excel based GUI to predict the torque vs. RPM curves for these engines. Dynamometer data from 229 Engine Master's engines consisting of a total of 5824 torque measurements from the dyno runs were fed into a Monte Carlo Neural Network algorithm to derive this torque vs. RPM model/ simulation.

The following video describes the data analysis, derivation and error analysis of this model. There is audio so un-mute to listen.

The next task will be to create a user friendly Excel based GUI to predict the power robbing bump discussed in the previous video. The Nearest Neighbor ML learning algorithm was used to derive this model.